In the classic Chinese novel Journey to the West, Monkey King’s golden staff can magically expand and shrink at will. For as long as there has been imagination there has been exploration for a material which can be freely adjusted in its hardness and softness, compression and expansion. In a 21st century laboratory in The Chinese University of Hong Kong (CUHK), a discovery has been made which breaks through to that.

Professor Lei XU and a team which includes Dr. Xiangying SHEN and Dr. Chenchao FANG, post-doctoral fellows, from the Department of Physics have for the first time discovered the close connection between the topology of a material and its elasticity. By deriving a specially configured packing-derived network, they came across the topological transition point to elasticity and have successfully produced, in the laboratory, a new type of smart elastic metamaterials. Professor Xu’s team began a project that was purely scientific research and then they discovered something they did not know was there, which is inspirational for the future development of metamaterials.

A network that determines the elasticity of a material

To simply illustrate a packing-derived network, Professor Xu gives the example of a box being filled by ping pong balls. At the beginning of the process, they move around randomly inside but eventually the box is filled so tightly that they jam together and movement ceases. This he calls the jamming point.

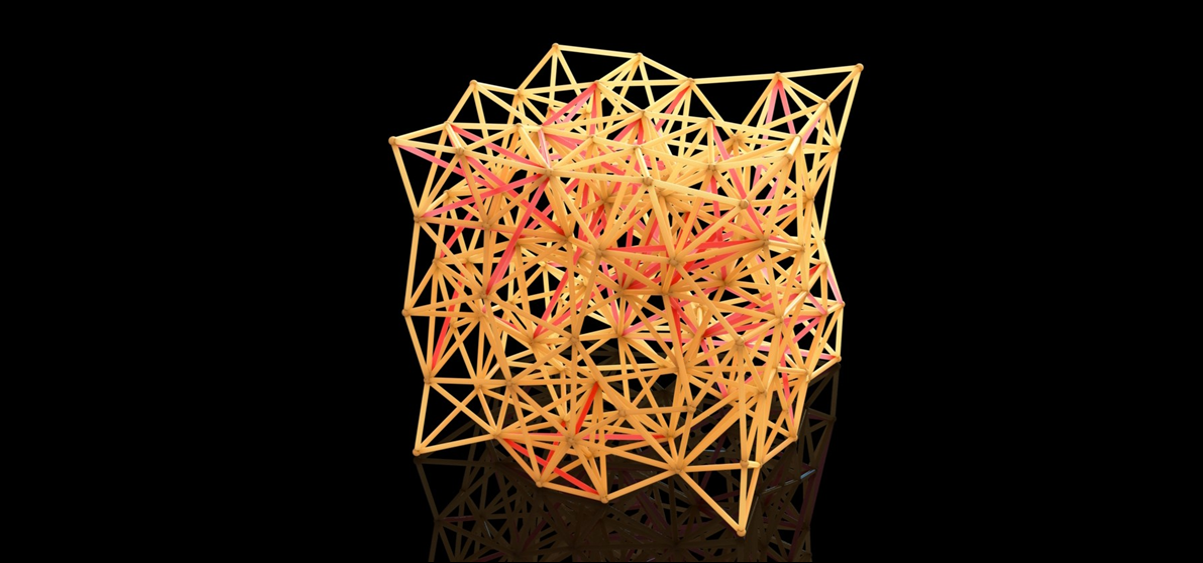

Professor Xu and his team devised the specially configured network through 3D printing which comprises nodes that correspond to the core of a particle and are linked by bonds. The particles are packed together so tightly that eventually the nodes, like the ping pong balls, reach a point where they jam. It is also when the system’s rigidity arises and changes from liquid-like to solid-like. Near this specific jamming point, the team has discovered that the topology of the material can begin to be altered and that is done by adding or subtracting the bonds between the nodes.

The most interesting feature of the network for Professor Xu is its ability to tune two independent moduli, “bulk” and “shear” – a modulus being the quantity that measures a substance’s resistance to being deformed elastically. The bulk modulus shows the level of difficulty in compressing a material. The shear modulus tells you how difficult it will be to deform the material by applying force parallel to its surface. For example, water has a very high bulk modulus rating because it is near impossible to compress it but it has a zero shear modulus because it can run everywhere under shear force. Professor Xu’s discovery can tune these two moduli continuously and independently in a powerful way, each without affecting the other, by changing the bonds or connections. They can be changed from near-liquid to hard-solid properties and back continuously. The super weapon from Monkey King, his magic staff, is coming into view.

“Being broadly tunable according to requirement is a smart material’s crucial property”, says Professor Xu. “A smart material is one that is flexible to changes in an external environment. Once you have a framework, you have the freedom to systematically change the properties in this one single framework and that ability is important for smart systems and smart materials,” he added.

In his basic research, Professor Xu has not set his mind ambitiously on manifesting mythological applications. “At this stage the network is a theoretical framework with some experimental realisation; a fabricated smart spring system and 3D-printed metamaterials with adjustable elastic properties. We can try to make real materials based on this structure.”

One potential application is material made for protection such as protective materials around packages or for clothes, headwear, or shoes to be worn in hazardous and industrial situations. Prototypes could be made for these to make the application more convincing. His team is willing to talk to industries to find out what materials they need and that they are open to different ideas on what will be brought about.

He further explains, “We were interested in the topological transition in our packing system and the jamming phenomena.” Professor Xu’s PhD supervisor at the University of Chicago, the United States, had this tradition of studying the packing problem. He was a famous researcher in this field and Xu was trained in this. “It’s a very active research area. When we further studied the transition, we found this topological transition which hadn’t been discovered by previous researchers. It was then that we had this idea to use this phenomenon to design smart materials.”

Thinking back to that mythical staff, it is tempting to recall science writer Arthur C Clarke’s ‘Third Law’ that ‘any sufficiently advanced technology is indistinguishable from magic’.

The project was carried out with the funding support earlier from the Research Grants Council of Hong Kong, the National Natural Science Foundation of China and the Guangdong Natural Science Fund in Professor Xu’s laboratory. Research findings have been published in the prestigious scientific journal Nature Materials. Full read to the research findings, please visit: https://www.nature.com/articles/s41563-021-01046-8.