Have you ever been on your cell phone and felt a warm glow on your cheek turn into a hot spot? That’s its lithium ion battery which can short circuit and burst into flames literally under your nose. Professor Yi-Chun Lu from The Chinese University of Hong Kong’s (CUHK) Faculty of Engineering has discovered a solution, a soluble polymer called PEG which is found in skin care cream and is totally beneficial to our chemical and heat sensitive skin. Professor Lu has introduced PEG into an aqueous lithium battery to protect the water and result in a battery that is stable. It makes having a cell phone next to your skin a whole lot safer.

Current lithium-ion (Li-ion) batteries are high energy, rechargeable, and near indispensable to your clutch of personal electronic accessories, like cell phones and laptops, and in the wider world of electronic devices. These batteries still heavily rely for power on electrolytes that are toxic and flammable. If you think those drawbacks might be minor, headlines will recall a series of fires in Samsung cell phones in 2016, and the grounding in 2014 of the entire Boeing 787 Dreamliner fleet from battery fires in their auxiliary power units. Less prominent incidents occur regularly.

Of course, there are ways to correct this. Enter the aqueous Li-ion battery in which the electrolyte is water based, making it nonflammable with no risk of explosion. Unfortunately, the water in the aqueous battery which provides stability reduces power and energy. Electrolysis occurs at a mere 1.23 volts, destabilising the battery operation and voltage output. Professor Lu said, “Research ploughed on though and introduced large quantities of salts to stabilise the water molecules and increase the voltage. Regrettably the salts are heavy, expensive and ecologically unfriendly.” Apart from the flammability factor, it was almost back to the beginning.

Professor Lu and her team were thinking beyond salts. They had in mind “molecular crowding” a common activity that occurs naturally in living cells where molecules get modified in a crowded environment because the activity of the water solvent is reduced owing to the changes in the water’s hydrogen-bonding structuring.

“The idea really came from thinking about the underlying need to lock down water. We had to look for a similar scenario, but in different fields,” explains Professor Lu. “I always encourage my students to be interdisciplinary in their research and to do that successfully, you have to look at the core of the problem and understand the fundamentals of what you seek, otherwise it is trial and error and you never get there.”

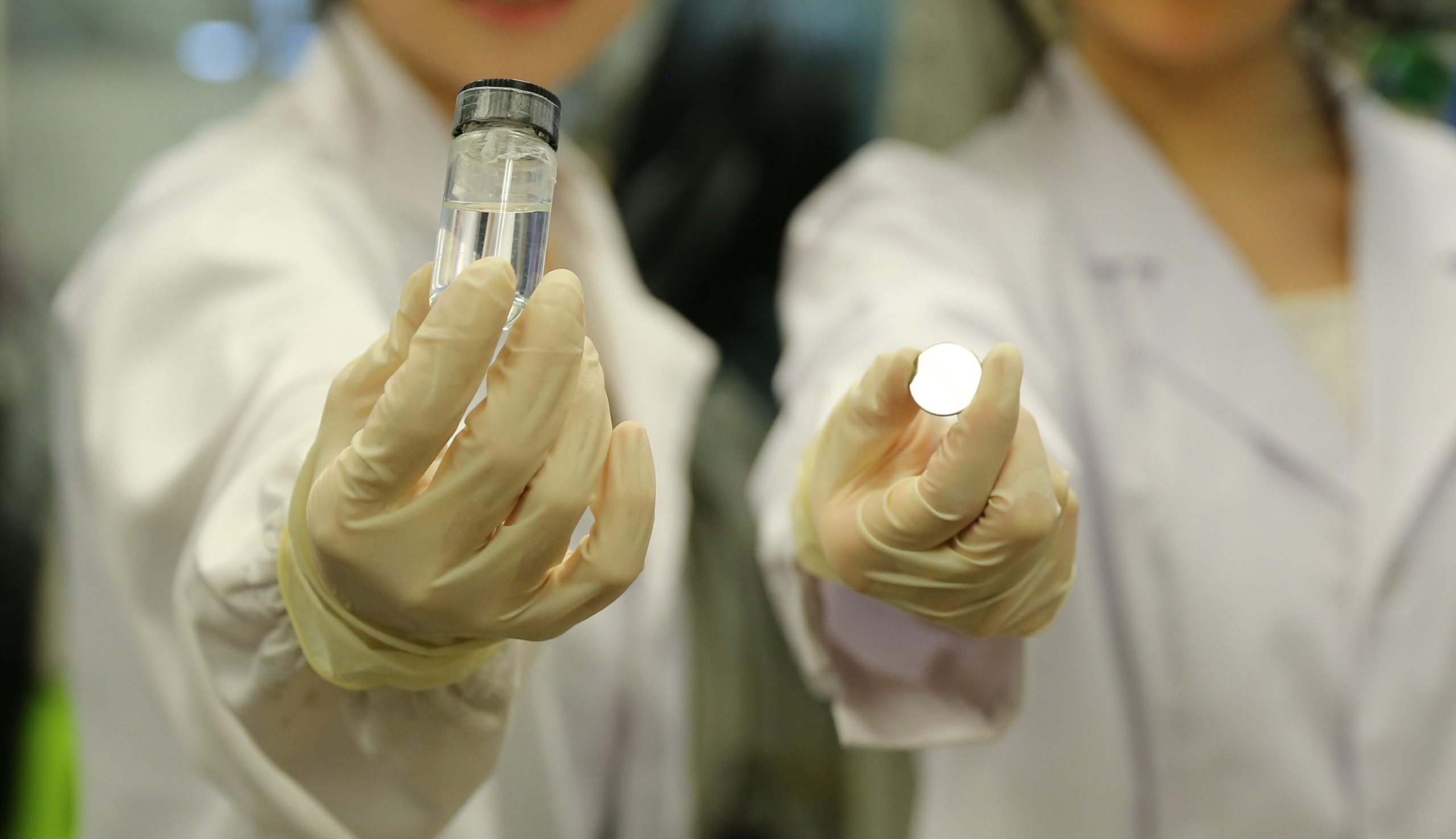

Having identified molecular crowding as a core solution, the team had to find something to replicate it in the electrolyte and this took them into the unlikely realm of the bathroom cabinet. They hit upon poly (ethyleneglycol) (PEG) —a water soluble polymer that can be introduced as easily into aqueous Li-ion batteries as it is into skin cream, toothpaste and energy drinks. “We quoted these examples simply to highlight the cleanness and safety of PEG,” explains Professor Lu.

This is a breakthrough. “This electrolyte enables the use of many electrode materials that cannot be used in the conventional aqueous electrolytes.” she says. The lower concentration of lithium salts which the PEG allows meant that the team could successfully expand the aqueous electrolyte stability window to 3.2 volts and demonstrate stable battery operation for delivering a high energy density of 75 -110Wh per kg over 300 cycles using this new electrolyte. It can even go up to 4.0 volts with gel coating. She emphasized that the common side reactions in aqueous Li-ion batteries were virtually eliminated and its performance was similar to existing Li-ion batteries but without the risk of fire. The new electrolyte is not easy to burn and a flammability test was conducted by the team to prove its fireproof characteristics.

A struggle in the development of batteries is always against weight. Professor Lu pointed out that whilst 80% to 85% of the weight of the traditional high-voltage aqueous Li-ion batteries is lithium salts, at a cost of about 20 US dollars per kilogram, the new aqueous Li-ion batteries are much lighter. The weight of lithium salts is down to 30% to 35% of the total and the cost is reduced to about 1 US dollar per kilogram. The reduction of lithium salt content in the electrolyte makes the battery much less damaging to the environment, when it is disposed of. In all, it is safer, it is lighter, it is cheaper and much less of a pollutant at the end of its life.

“The consequences of this research are not limited to the system we demonstrated in ‘Nature Materials’ magazine,” says Professor Lu, “It is impressive but it’s just the beginning. Now we are in a much better position to deliver high density electrical power in a stable aqueous environment. There are batteries operating in industrial and generating situations which are potentially still dangerous. We need safety. It’s a top priority but we need power too. The rise of the aqueous battery leads to both. People who are working in the batteries field are very excited. I am getting emails from everywhere.” A patent has been applied for. Work continues to increase the voltage of the electrolyte and enhance its stability. It is expected to introduce the product to market in 3 to 5 years.

Photo by Stanley Yip & Alex Yiu