You might not have heard of them, but biofilms are everywhere. They form within our bodies: you’ll be familiar with them in the form of the plaque that clings tenaciously to our teeth. That plaque can cause tooth decay, but that’s just the start of the havoc biofilms can wreak, building up in the body and clinging to both the external and internal surfaces of much of the food that we eat, inflections are thus caused: according to an early study by the National Institutes of Health (NIH), biofilms are associated with 80% of all human infections. They’re a particular problem when they accumulate on medical implants, which lack the protection offered to the body by the immune system and are thus prone to be colonised by bacterial cells.

New approach to tackle biofilms deep inside human body

Biofilms form when a collection of microbes sense a nearby surface and decide to stick to it. After the formation of biofilms, those microbes become embedded within a matrix of so-called extracellular polymeric substances (EPS), a mixture of polysaccharides, proteins, nucleic acids and lipids that the microbes mostly excrete themselves, which forms a kind of city or motherboard for the microbes, offering them protection. That means they’re often resistant to treatment and incredibly hard to remove from surfaces.

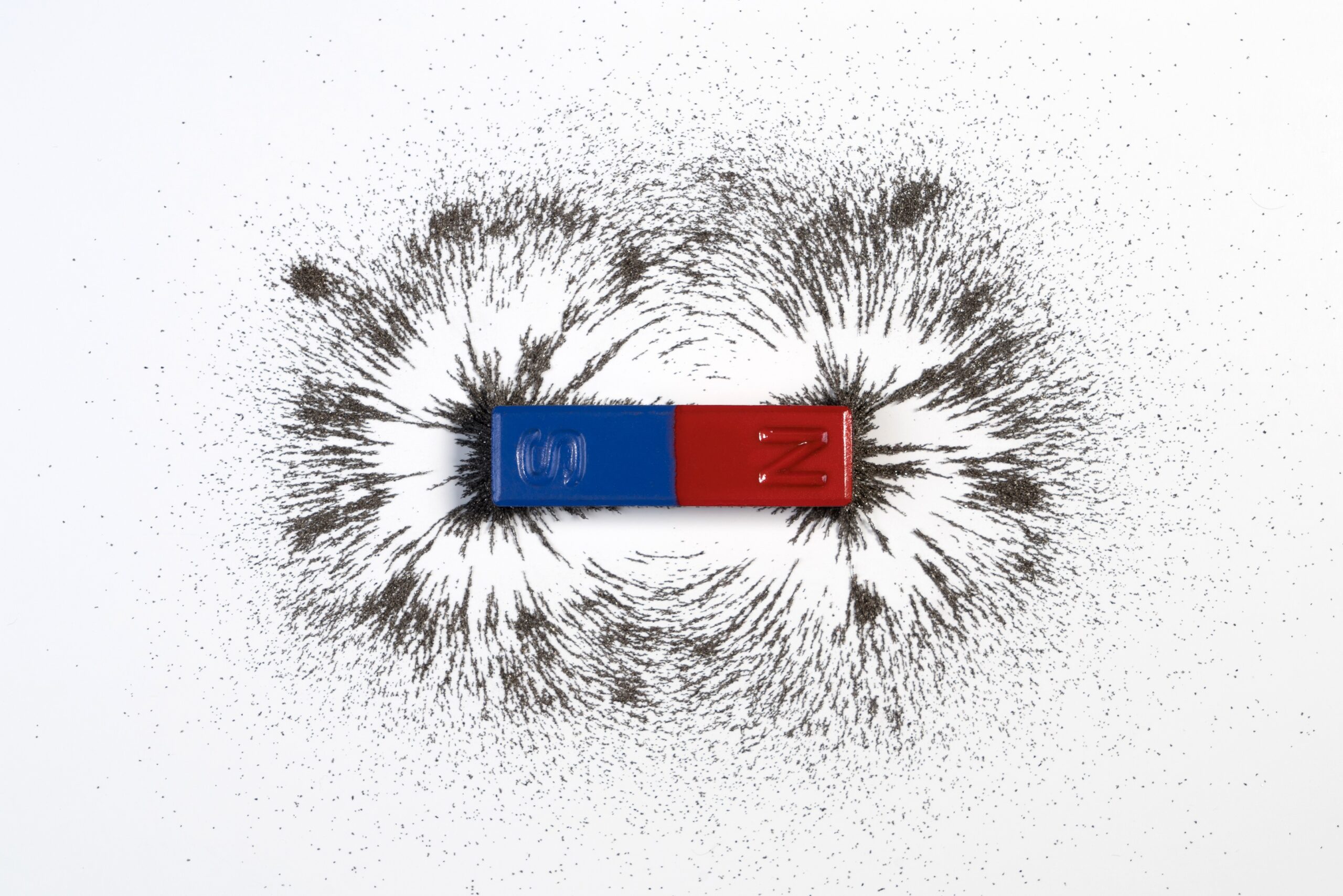

This is where the work of a research team led by Professor Zhang Li from The Chinese University of Hong Kong (CUHK)’s Faculty of Engineering comes in. The team has pioneered the use of magnetic hydrogel micromachines: minuscule machines that can be moved around complicated, hard-to-access environments inside the body using magnets, meaning they can visit the site of biofilm and precisely target it for eradication, both by physically disrupting it and by releasing antibiotics. In a study recently published in the leading scientific journal Advanced Intelligent Systems, the team showed that the machines were effective at killing off biofilms inside challenging environments.

“Biofilms are difficult to eliminate when they are associated with implant infection,” says Professor Zhang. “The EPS matrix provides a physical barrier to protect the bacterial cells from environmental threats, such as water flow or antibiotics; mechanical disruption is needed to remove the biofilm effectively. Medical implants are often located in hard-to-reach locations in the human body, which creates challenges for effective treatment of biofilm infections. Antibiotics used to be effective means to treat microbial infections. However, the emergence of superbugs – antibiotic-resistant bacteria – and the overuse of antibiotics in recent years has made it necessary to develop new approaches to treat microbial infections.”

Micromachines achieve controlled release of drug

To eradicate biofilm, the micromachines first exert physical force that disrupts it, then follow up with chemical agents that continue the job. The machines are made from a thermosensitive magnetic hydrogel, with tiny hydrogel compartments that store those agents – in the case of the recent study, hydrogen peroxide, which is carried to the affected area and then released when heat is applied to the machines. The really clever bit is that the magnetic component of the machines consists of iron oxide nanoparticles, and those also act as a catalyst, helping to transform the hydrogen peroxide into a form that can effectively fight the biofilm. This precise targeting has the advantage of reducing the quantity of antibacterial agents that need to be used. The magnets that control the machines’ movements come in two varieties: one is used to generate a uniform, rotating magnetic field, while the other generates a gradient field that drags the micromachine while rotating. The uniform rotating field controls the forward or backward movements of the micromachines in the tube. In contrast, the gradient rotating field is used to strengthen the cleaning ability in specific sites.

“Thermosensitive hydrogel has been widely investigated as a carrier for controlled drug release,” says Professor Zhang. “Our team previously conducted a study that incorporated iron particles into the thermosensitive hydrogel to make it responsive to magnets. We then further used this as a micromachine to fight biofilms.”

In the recently published study, the new technology proved startlingly effective. The study involved E. coli and B. cereus biofilms, both bacteria that can cause serious sickness in humans, testing the machines inside tubes that mimic the sort of challenging physical environment where biofilms are often present within the body, such as in medical devices. The machines removed the biofilms within five minutes, destroying 99.3% of the bacteria. Next, says Professor Zhang, the team will move towards preparing the system for use inside the human body.

“We will work on improving the performance of the antibiofilm micromachines with respect to a specific application site. We are now discussing with our medical partners a suitable application scenario. At the same time, we are planning to do animal experiments with the improved micromachine this year. We are also working on human-scale magnetic actuation systems compatible with clinical imaging modalities for application in patients.”

The machines might also ultimately have other uses beyond biofilm eradication. They could, for example, be used for targeted drug delivery in some of the hardest places to reach inside the body. Professor Zhang adds that they could also have industrial applications, such as the targeted cleaning of the inside of complicated machinery.